Sunraise developed the SE 15 in response to our loyal HP 15 customers who liked it’s size and production speeds, yet wanted some of the features found on our large format thermographers incorporated into the HP 15. The result was a machine with superior capability in productivity and flexible operation allowing the operator greater control over the final product.

The SE 15 features state-of-the-art ceramic fiber heaters and ensure even heat distribution. To conserve energy and maintain the ambient temperature outside the heating section , Sunraise used the same high tech insulation that NASA uses on its spacecraft. The heating and cooling sections of the SE models can be adjusted up or down and locked into place allowing for a variety of substrates.

For ease of operation, the SE 15 features a front conveyor clutch that stops the in-feed conveyor independent from the rest of the conveyor for operator convenience.

The Vacuum Inverter with digital LED read out allows you to increase or decrease vacuum with high precision.

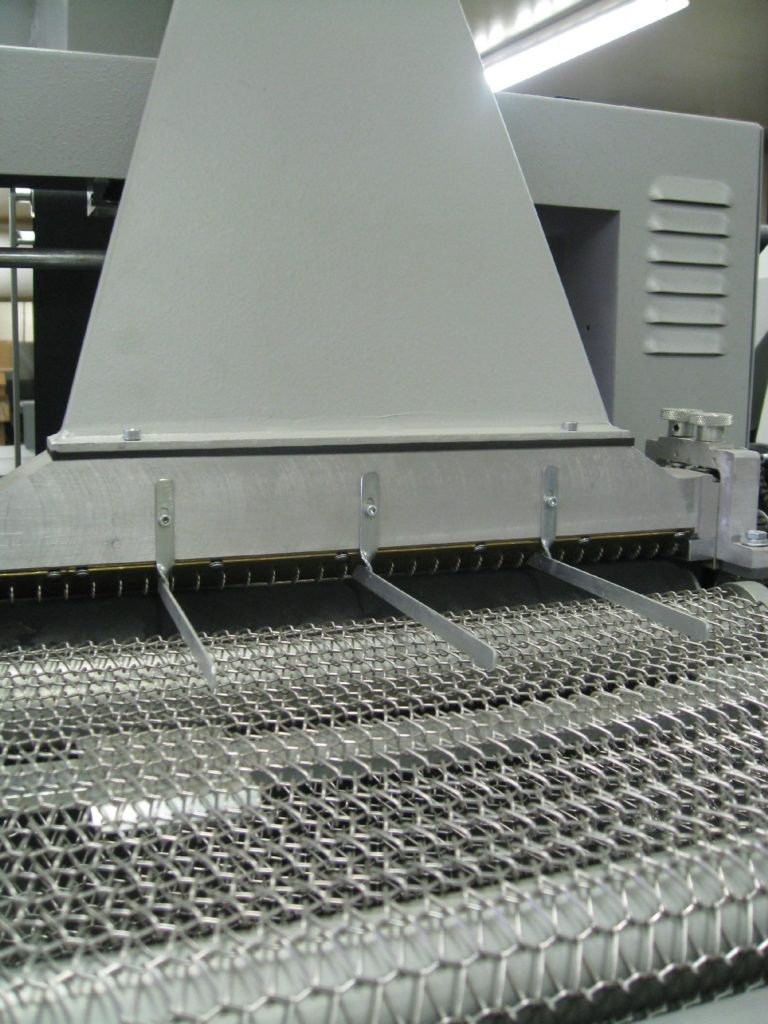

The SE 15 is equipped with the industry’s only molded airtight cast aluminum vacuum head which focuses vacuum precisely to the stock. This efficient high precision assembly is a Sunraise exclusive.

The front conveyor clutch stops the in-feed conveyor, providing operators more convenience and reduced fatigue during setup.

The powdering section on SE models have a molded airtight cast aluminum vacuum head, an industry exclusive from Sunraise! The assembly which can be adjusted to multiple levels, focuses the vacuum precisely to the surface of the stock producing a crisp and clean final product. A vacuum inverter allows you to increase or decrease vacuum by minimizing air turbulence in the vacuuming process which reduces wear and tear on thermographic resins.

The innovative features and ease-of-use design for our SE Series came from listening to our customers needs and suggestions. Our commitment to research and development has made Sunraise thermographers the #1 choice in the world for high production thermography equipment. You can customer order your SE Series model with dual powdering or dual heating units. If you produce heat transfer you can order our SE Powdering Sections as fully functional stand alone modules. Whatever your needs, Sunraise can provide you with the equipment you need.

The SE 15 is equipped with the industry’s only molded airtight cast aluminum vacuum head

which focuses vacuum precisely to the stock.

This effiicent high precision assembly is a Sunraise

exclusive.

Conveyor mesh rollers in the heater section have an internal tracking system that provides for 0 slippage and side to side

movement.

SE 15 SPECIFICATIONS

| ELECTRICAL REQUIREMENTS | FLOOR SPACE | HEAT |

| 208 or 220V/ 3 Phase, 60 amps 60 cycle (can be modified to accommodate all international standards) | Length: 17ft 5.18 m Height: 57in 1.45m Width: 38in .96m | 12,000 watts using both zones or 7,500 watts for a single zone. |

| STOCK SIZE | WEIGHT | MAXIMUM PRODUCTION SPEED |

| 15X20 381 mm x 508 mm | 1,225 lbs 555.65kg | 10,000 iph tested on 8.5×11 60lb stock |